Coed Cymru was set up in 1985 as an all-Wales initiative to promote sustainable woodland management and the use of locally grown timber. It is a partnership of public, private, academic and third sector bodies working through the charitable company Coed Cymru Cyf.

Housing from home-grown timber

Background to Tŷ Unnos

In 2006/7 a partnership consisting of the Welsh School of Architecture, University of Wales Bangor and and Coed Cymru undertook a brief study, funded by the Countryside Council for Wales and the Wales Forest Business Partnership to establish the feasibility of producing social housing from home-grown softwood.

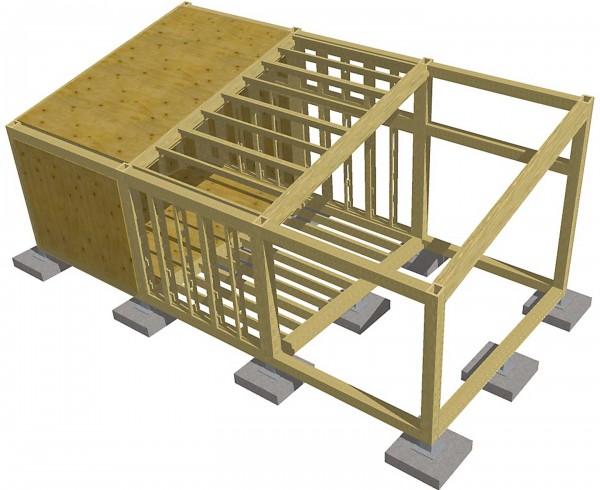

The study led to a report that proposed a radical departure from current practice; a whole house construction system consisting of engineered components designed to utilise home-grown softwood. View the CCW Ty Unnos feasability report.

This was necessary as Welsh grown Sitka spruce, which is sawn and machine graded for construction to C16, was perceived by the timber frame industry to be too twisty, knotty and fast grown to use in their designs.

In 2010 the Coed Cymru project – ‘Improving the supply chain for low value Welsh timber’ – commenced under the Rural Development Plan for Wales 2007-2013 which is funded by the Welsh Government and the European Agricultural Fund for Rural Development. This enabled the Tŷ Unnos project to take action and build capacity across the whole supply chain:

- from forest to finished product

- develop integrated working practices

- provide information, encouragement and hands-on support.

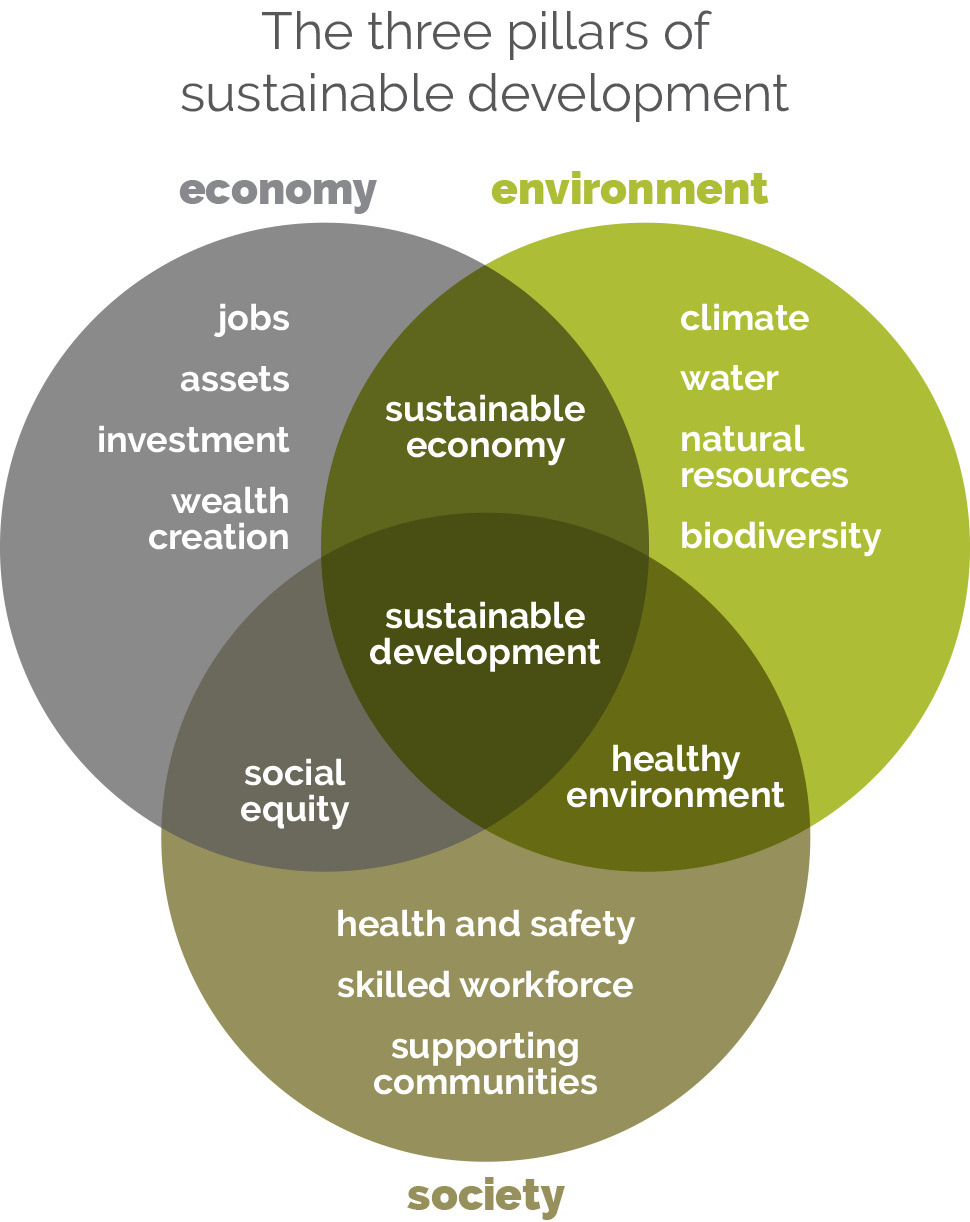

The cultural aim

To use the resources from Wales Forest Estate to obtain maximum multiple benefit during the growing life and carry the benefits into timber products that provide, education, employment, healthy efficient homes and lock in carbon.

To Promote Welsh Government strategy and legislation on ‘wellbeing’, the ‘environment’ and ‘Natural resources’ by planting, growing and using trees to provide a truly sustainable environment, economy and society.

Creating a partnership

Wales’ academic sector; timber industry; and manufacturers were bought together in the project to develop a system from Welsh timber.

The robust supply-chain / our vision:

- Add value to locally grown Welsh timber

- From well managed forests delivering quality timber outcomes across society

- Trees are thinned, harvested and extracted, supporting a highly skilled and efficient contractor industry

- Saw logs travels a short distance to the sawmill

- Logs are sawn, structurally graded and dried at a local sawmill, requiring skill and

- Buildings designed by Architects and Structural Engineers that appreciate the character of home-grown timber

- Manufactured by regional groups of businesses

- Erected by local building contractors

- Robust monitoring and feedback.

To create healthy, energy efficient, affordable buildings.

Using Welsh timber

Wales has 150,000 hectares of coniferous plantations, producing around one million tonnes of softwood per annum 70% of this is Sitka spruce.

Softwood planting policy in the past four decades, focussed on yield class (‘volume’), has determined the timber that is available today. The forecast for volume of logs available to the market is downwards and risk of disease is high due to limited species and low genetic diversity. Timber quality is being reduced due to genetic selection, planting spacing, speed of growth and thinning regimes. Wood properties and uses of spruce in Britain.

In 2007 all of the modern timber frame manufacturers in Wales (and the UK) used imported C24 softwoods due to its availability, consistency, greater stability and strength.

Welsh spruce in comparison to imported spruce:

- Grows much faster due to our mild climate and long growing season

- Produces timber of lower density due to the fast growth rate

- Has heavier branching and larger knots due to increased planting spacing to limit thinning costs

- Has a tendency to twist during drying – cited by timber frame manufacturers as their main reason for not using it

- Is only structurally machine graded to C16 by British sawmills – it is perceived to be uneconomic to grade to C24 due to the ratio of passes to failures.

Therefore a simple substitution of imported C24 with home- grown C16 was not deemed possible. For a system to be adopted generally and to maximise the use of Welsh timber it would need to stabilise the main structural components and eliminate the use of conventional trussed rafters (which use imported timber).

Developing the System

Collaborative working

The multi-disciplinary team of timber professionals formed to prototype, test, and develop home grown timber components came from the academic, public and private sectors. This new way of collaborative working necessitated a level of commitment, co-operation and communication skills previously unseen in the Welsh Timber Sector. Designing to a high level of performance lead to a successful bid to the UK Government Technology Strategy Board and Aggregates Levy.

The Name

The System was named ‘Tŷ Unnos’ to convey a fast and adaptable building system making use of local material and local labour – Tŷ Unnos literally translated as “a house in one night” from the Welsh folk tradition of erecting a house overnight on vacant land and claiming it as a home.

The Timber

Home-grown Sitka Spruce, Douglas Fir, and possibly Larch, graded to structural strength class – C16.

The Components

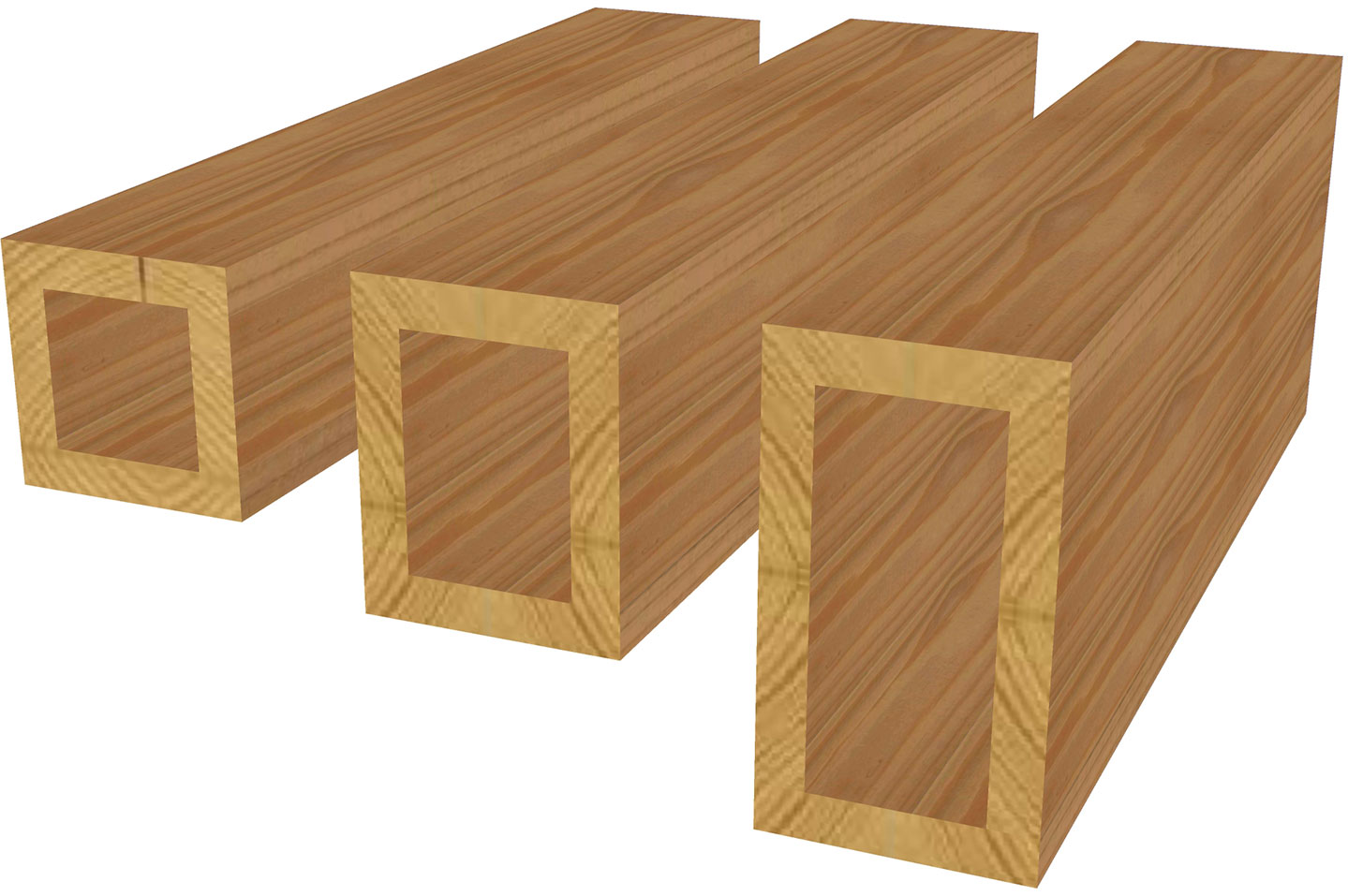

The early system consisted of two engineered timber components;

a hollow box section beam

and a ladder beam.

Combined with frame connectors and infill panels, the engineered components can form an innovative whole building construction system. The ladder trusses and hollow beams compliment blown cellulose insulation. eg Warmcel.

Intellectual Property Rights ‘Open Source’

All Coed Cymru’s charitable work is put into the public domain as ‘open source’ information.

Stringent Testing and Certification

The Eurocodes convention in prototyping and testing components has been followed.

Using Welsh timber in construction

For in depth information visit the following pages:

Outcomes

Welsh timber can be used to build sustainable, affordable, energy efficient housing using the Tŷ Unnos system.

Wales can add value to its locally grown resource and create jobs within forestry, milling, manufacture, construction, design, education and knowledge transfer.

The use of Welsh timber in Tŷ Unnos components has had a versatility beyond the initial focus on affordable housing. The breadth of completed projects can be seen in the Portfolio.

‘Improving the supply chain for low value Welsh timber’ project successfully engaged the whole Welsh timber supply chain and has won a number of awards and commendations.

A network of experienced Tŷ Unnos professionals are available, and can be contacted directly through the links on the portfolio pages.